Computerized Numerical Control (CNC) is the system through which an operator can control the machining work of a tool. The management is carried out via a control panel and a software program. The commands executed from here reach the machine to comply with the established guidelines.

Numerical control is responsible for controlling all the machine's movements. Among them, not only the cutting and its precision but also the speed, type of movement, etc. In this way, much more precise, accurate, and personalized results are achieved.

How CNC Works

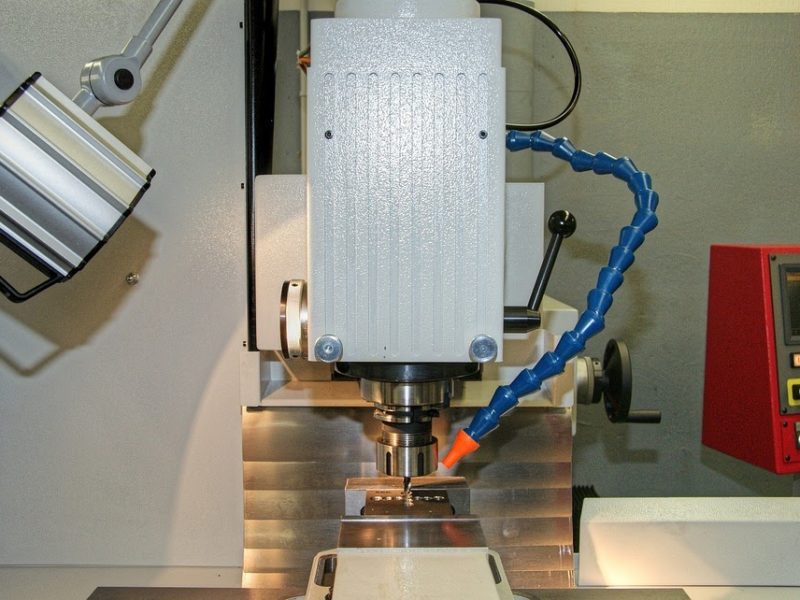

The operation of computerized numerical control is based on positioning over the X, Y, and Z axes. From these three axes, different automatic machining tasks can be performed on a piece. The most common are cutting, drilling, milling, threading, or roughing.

The first task carried out is the design of the piece on the computer using CAD software. CAD software (computer-aided design) is used to create and modify any design. A drawing technique with which to design the different properties in terms of color, layer, style, and material of a piece.

Once the final design is available, the operator goes to the control panel of the machining machine to indicate the necessary commands for the piece's manufacturing. The movements that the machine will perform are integrated into the CNC through codes with various determined keys.

The main commands given to the tool are the feed rate, depth, start or stop. However, it will all depend on both the machine being used and the piece and its desired design. Also, within these commands, the tool change, positioning, and other directional variables in the movements can be included.

This is why each machine has its own different CNC program. Lathes and milling machines are the most common machining machines. But within them, there are a series of types that perform different tasks with specific pieces. The computerized numerical control can be different in all these tools.

Uses and Applications of Computer Numerical Control

CNC machining is already used in both large companies and small workshops, factories, and businesses. Specifically, it is used in cabinetry and carpentry workshops, for interior design work, industrial design, textile industry, and the manufacture of all types of metal pieces.

The major industrial sectors use CNC machines as essential elements. The aeronautical, aerospace, steel, wind, automotive sectors, etc., employ machines of this type for the manufacture of all their parts and components. Turbines, propellers, fuselage elements, parts for cars, ships, trains, etc.

CNC technology is also used for the electrical industry, as well as in any that is dedicated to the manufacture or extraction of metal. In reality, any type of industry today requires the use of computerized numerical control.

All companies that perform cutting, carving, drilling, threading, or roughing work on pieces of greater or lesser size will use CNC in their processes.

Advantages of using CNC

Computer numerical control is a system that has completely revolutionized the industry. Its use provides a series of more than notable advantages to different industrial sectors.

The main advantage has to do with the high speed of production. Factories, workshops, and industries that use CNC machining tools have gained in productivity. In fact, there are systems that can work 24 hours and at a very high level of production to meet the demands and needs of the market.

CNC machining also offers great versatility and flexibility. The different commands executed from the CNC control panel allow the machine to perform different tasks. Thus, a large number of designs can be obtained and operate on pieces of different sizes and shapes.

On the other hand, the use of CNC allows for better finishes on the surface of the piece. The degree of precision and accuracy is maximum. The computerized work minimizes the risk of error, achieving in turn a better final polish on the manufactured piece. Furthermore, the operator only has to enter the data into the CNC control panel for the machine to do all the work. This means that worker manipulation is minimal, greatly reducing the risks of a possible accident. CNC machines are much safer than manual ones.