According to many experts, turning was the first machining operation that gave rise to a machine tool. The lathe uses very basic movements that have helped it become one of the most used machines in machining workshops. But these movements would not be possible without the lathe axes , which are a key piece for this machining.

Lathe movements

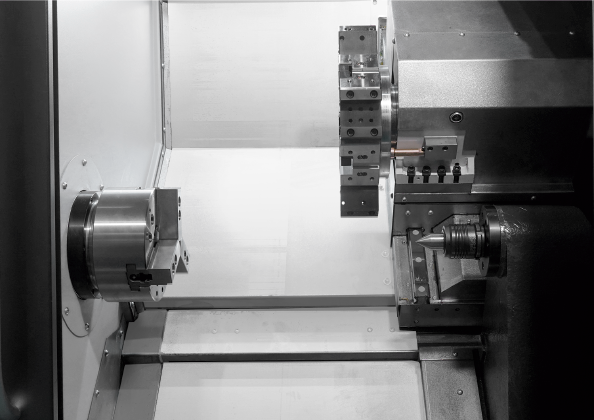

There are multiple types of lathes on the market. We can find automatic, parallel, vertical and CNC computerized numerical control lathes; The latter are the most famous thanks to the multiple benefits and functionalities for the industry. Each lathe, except for the CNC, is capable of performing all specific jobs and tasks. Thus, a lathe is capable of creating cylindrical or cone-shaped pieces, but it can also drill, cut, sand or slot these pieces. It all depends on the lathe, the tool used and the movement performed.

Before talking about the axes of the lathe, it is important to talk about the movements that this machine tool performs since axes and movement go hand in hand in turning. The piece is the one that rotates and the movement it makes is usually called “working movement.” Curiously, although the piece rotates, it is the tool that approaches the piece to make the cut. With this system the lathe has three movements:

- Rotational movement or cutting movement due to rotation of the piece. This is the most used movement. The piece is placed on an axis that rotates, causing the piece itself to rotate on itself. For stock machining to work, a cutting edge must be used that allows material removal. If the right tool is chosen, as well as the best conditions to do the work, the results will be very precise.

- Forward movement. In this movement of the lathe, it is the cutting tool that moves parallel to the piece, through a straight movement. This movement serves to define the contour of the part to be machined.

- Penetration or depth movement. In this movement it is the tool that enters the piece making a cut and determining the depth of the cuts made.

The axes of the lathe

In numerically controlled machine tools, the concept of axes is used to call the directions followed by the different displacements of the moving parts of the machine. Within these parts are the table, the transverse or longitudinal carriage. There are only two axes of the lathe: X and Z. Between these two axes, the Z makes a longitudinal movement following the main axis of the lathe; For its part, the X axis is responsible for making the transversal and perpendicular movement to the main axis of the lathe.

And how are the movements related to the axes of the lathe? Here we find that in the three types of movements described above (rotation, advance and penetration), the axes play a key role. The cutting or rotating movement occurs between the surface of the part and the moving tool; In this movement, the piece rotates in the direction of the Z axis while the tool can move in any of the two axes of the lathe.

In the forward movement, the tool can also move along the two axes that make up this machine tool; If it moves along the Z axis, then a cylinder is applied to the piece; On the contrary, if it moves along the X axis, we say that the workpiece is facing . In the last movement, that of depth of cut or penetration, the tool will always move along the X axis with the purpose of eliminating part of the upper layer of the piece.

Three-axis machining

Within the computerized numerical control machine tools we find that there are three-axis lathes . These are capable of performing machining in which the tools, which are controlled through a computer, move using three axes. The movements made by the tools of these machines are very precise and high speed. The movement carried out by these axes is done through the support that holds the piece.

This type of lathes that operate with three axes provide multiple advantages for workshops. For example, they reduce working time , since the pieces do not need to be positioned multiple times by the operator; The finish is much better , it is more stylized thanks to the tangential movements made by the tool while the lathe is working, and, finally, it is possible to create very complex pieces.