The lathe is one of the machines most commonly used in small mechanical industries and repair shops . One of the most common or traditional types is the parallel lathe. Easy to use, numerous parallel lathe operations are currently known for different applications.

The main use of the parallel lathe is to transform a solid object into a piece of previously defined shapes and dimensions . To do this, what is done is to rotate the object around the symmetry axis of the parallel lathe. In this way, the chip, the solid material of the object, is removed and the required shape is given.

The most common operations of the parallel lathe

The parallel lathe is used to cut metal and turn it (i.e. shape it). It is an essential mechanical drive tool in any machining workshop, as it allows many specific jobs to be carried out.

Parallel lathe drilling

Drilling is one of the most used parallel lathe operations in any machining workshop. What is done here is to remove the chip with a circular cutting movement using twist drills. For this, with the lathe a forward movement is used in the direction of the axis of rotation.

Parallel lathe drilling is usually carried out on the workpiece in combination with other lathe work. This way you can drill on one side of the piece, taking advantage of the fact that it is perfectly supported. Special care must be taken in cases where the drill is small.

Parallel lathe parting

Parting off with the parallel lathe is an operation that consists of cutting or separating part of a piece . This task is usually carried out in the machining of small pieces and with machines with bar feed.

Parting off is usually one of the last operations on the parallel lathe. That is why you have to take special care and use a precision tool; It is also advisable to do it by applying a coolant, manually or automatically.

Parallel lathe boring

Boring is a machining operation that is carried out on part holes in order to obtain greater precision and lower surface roughness . In this case, the size of the hole will have to be taken into account to carry out the work. However, it can be carried out in both cylindrical and conical holes. Conical borings are recommended to be done with CNC lathes, since it requires a lot of skill to do them with manual lathes.

With boring, what is achieved is to enlarge or improve the quality of an existing hole .

Facing with parallel lathe

Facing is an operation that consists of machining the end of a piece and in the plane perpendicular to the axis of rotation of the parallel lathe. The operator must place the part at an angle of 120 degrees with respect to the tool holder. Thus, what is obtained is a flat surface allowing the tool to advance across the front face of the piece.

The piece, meanwhile, moves in a rotary manner and is normally held by a vice. Facing can be done from the outside in or from the center out .

Parallel lathe threading

Threading with a parallel lathe is one of the most demanding operations. The cutting forces are higher and the cutting radius for threading is smaller. The feed rate in this machining process must correspond to the pitch of the thread. That is why, to carry out this operation, the thread profile that you want to machine is usually already adapted.

When it is necessary to produce large quantities of threaded parts, rolling threading is used (instead of traditional chip removal) or threading with numerical control lathes. The difference here is that the fibers of the material are not cut, but displaced. Thus, manufacturing times are reduced and the lathe lasts longer.

Cylindrical or cylindrical turning

Cylindrical turning or cylinder turning is another of the operations of the parallel lathe. It can be of two different types:

- External cylinder : the blade moves longitudinally to the piece and parallel to the axis of the machine, leaving a diameter smaller than the original

- Internal cylinder : same blade displacement as the previous one, but in this case leaving a diameter larger than the original

To ensure maximum quality in this operation, it is necessary that the parallel lathe have well-adjusted alignment and centricity.

Conical turning

Conical turning is a machining operation that consists of carving surfaces of revolution with generators that are not parallel . This task can be carried out on the parallel lathe using three different methods:

- The method using the upper carriage

- With a conical turning device

- Moving the tailstock

Along with these parallel lathe operations, others that can be performed are knurling , reaming or grooving .

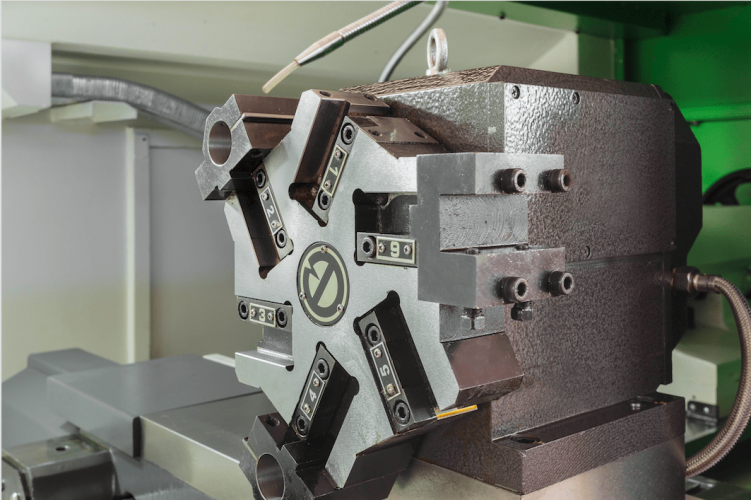

Graphic View of Turning operations